| 13/21 | N - Facing the end of another bolster swivel plate Return to MSR&LHA Home page |

|

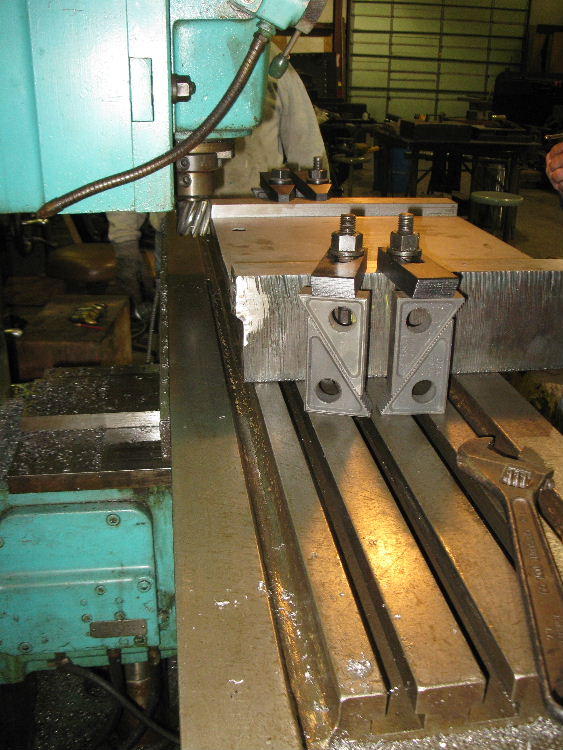

Fixing a swivel plate mistake. The plate was machined too narrow, because its mounting groove was after-the-fact found in need of being trued up on a milling machine. This of course made the plate too narrow, so the only solution was to built up the side of the plate, and cut it down again! Note that only the portion of the plate to fit into the bolster groove was welded up, which took at most two hours.

Photo by Bill Liebman |